The project’s experimental counterparts faced difficulty in choosing the right tool design and process parameters due to high upfront costs and operational demands. This was largely due to the reliance of liquid forging on costly tooling and process designs that are often refined through trial-and-error, leading to inefficiencies and inconsistencies in outcomes.

A robust predictive tool is therefore essential for assessing whether a part can be successfully forged, determining optimal process parameters, and ensuring the final product is free from defects. This empowers manufacturers to make informed decisions before committing significant financial or material resources.

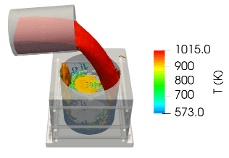

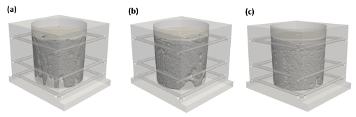

Researchers at A*STAR IHPC developed comprehensive computational models to simulate the liquid-forging process. A key component is a CFD-based melt-pouring model that helps predict and prevent defects arising during the pouring stage. The outputs of this model are then integrated with a Finite Element Model (FEM) to simulate the subsequent forging stage, evaluating applied pressure, material flow, and susceptibility to crack formation. Together, these coupled models create an end-to-end virtual experimentation framework that supports optimal process design and enhances the reliability of liquid-forged components.

The project introduces several key innovations:

- Predictive, model-driven process design— By developing physics-based CFD and FEM models, the research introduces a predictive framework that evaluates viable designs and processing parameters virtually, reducing reliance on physical trials and accelerating development cycles.

- Integrated, end-to-end virtualisation of the liquid forging workflow—While existing tools often address only isolated stages, this project couples melt-pouring CFD simulations with downstream FEM forging analyses to form an end-to-end digital workflow. This holistic view enables early detection of pouring-induced defects and their downstream effects on deformation and crack susceptibility, allowing manufacturers to resolve issues before they arise in production.

Through detailed modelling of melt flow, heat transfer, solidification, and forged material response, the research provides deeper insight into how defects originate and propagate—knowledge that cannot easily be obtained from physical trials alone. This new knowledge enables targeted optimisation instead of broad parameter sweeping.

The CFD melt-pouring model involves resolving large transient, three-dimensional multiphase flow, heat transfer, and solidification. These complex simulations demand significant compute power and memory bandwidth. High Performance Computing (HPC) was essential in enabling these computationally intensive, high-resolution simulations to run within practical timeframes. By leveraging HPC, multiple parameter variations could be executed in parallel rather than sequentially, dramatically reducing turnaround time and transforming the workflow from trial-and-error to rapid virtual experimentation.

If we leverage the use of multiple CPUs (e.g., 256 CPUs) on NSCC Singapore’s HPC cluster, the computational time of one simulation can be reduced by more than 80%. This implies that a CFD simulation that typically needs 5 days to complete with a 40-core workstation, can be completed in less than 24 hours using HPC cluster. Multiple jobs can also be run in parallel with the HPC clusters, which enables efficient parameter sweeping when simulating the pouring stage of liquid forging.

Although the modelling framework is developed for liquid forging of components for Physical Vapor Deposition (PVD) chambers, the underlying approach has broad applicability across multiple manufacturing sectors. The integrated CFD–FEM workflow can be readily adapted to other processes involving melt flow, solidification, and deformation—such as die casting, semi-solid forming, investment casting, additive manufacturing etc. This directly supports the wider digital transformation of traditional metalworking industries, many of which still rely heavily on trial and error methods.

Industries with high performance requirements—such as aerospace, automotive and energy—can also benefit from more accurate, predictive modelling. With future development of reduced-order or AI-based models, this workflow could eventually become a real-time digital twin for manufacturing lines.

Beyond the technical benefits, this project contributes to the wider community by building stronger capabilities among SMEs. Access to digital tools allows manufacturers to refine their processes, produce more consistent outcomes and make better use of resources. This supports more efficient and sustainable practices across the sector and reduces the overall environmental footprint.

Early results are already being seen by the teams carrying out the liquid forging experiments. The simulations developed by A*STAR IHPC offers clear guidance on the press tonnage required for potential parts that can be liquid forged with minimal defects. These insights help support strategic decisions on future investments—such as whether a larger forging press may be needed—to strengthen Singapore’s ability to supply high-quality PVD chamber components.

In the longer term, the wider manufacturing sector is expected to benefit as digital tools and more sustainable practices gradually become part of standard operations. While these shifts will take time, continued capability building and growing industry familiarity with digital methods provide a strong foundation. As more companies adopt these approaches, Singapore’s manufacturing ecosystem will be better positioned to innovate, compete and deliver higher-quality outcomes across a broader range of applications.

“HPC provides the fidelity and scale needed to model complex manufacturing processes — and with NSCC Singapore’s ASPIRE 2A supercomputer, we can now simulate the full liquid-forging workflow with unprecedented detail. By replacing trial-and-error with physics-based, data-driven insight, HPC enables us to predict defects, optimise parameters, and guide equipment investment with greater confidence. In modern manufacturing, these capabilities form the foundation for digital transformation and more consistent, reliable outcomes.”

Jerry Quek

Senior Principal Scientist I

Advanced Manufacturing and Semiconductor (AMS), A*STAR IHPC