Disordered materials are found across both natural and engineered systems, in everything from geological minerals to advanced catalytic and energy applications. Despite their importance, they remain underrepresented in materials databases due to their structural complexity and the limitations of conventional modelling techniques. Current simulation methods fall short in predicting whether such materials can be synthesised or how they will behave under real-world conditions, creating a bottleneck in materials innovation.

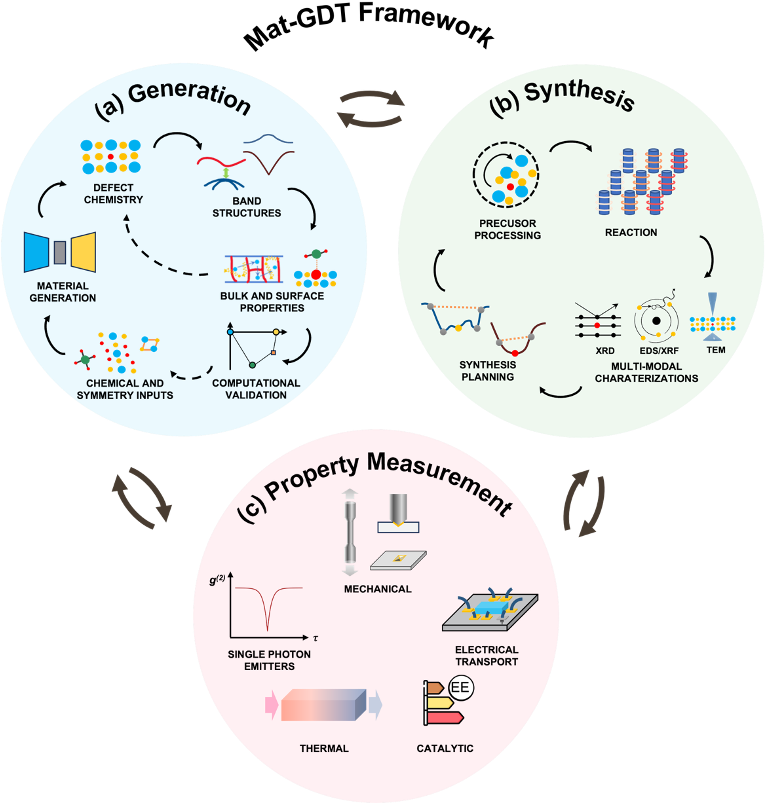

Mat-GDT offers a scalable, smarter framework to bridge this gap. By combining machine learning algorithms with HPC and AI, it enables the rapid generation of realistic atomic models and accelerates the evaluation of their physical and chemical properties.

This approach not only improves the reliability of theoretical predictions, but also enables a scalable pathway for identifying promising materials for experimentation—broadening the scope of what’s possible in materials science.

The innovation behind Mat-GDT lies in its shift from traditional trial-and-error methods to a more targeted, property-directed discovery process. Instead of testing known materials to see what they can do, the framework begins with a specific function, such as high thermal conductivity or structural robustness and works backward to identify candidate material structures that could deliver those outcomes.

Central to this process is WyFormer, a symmetry-aware generative AI model designed to create crystal structures that follow physical laws of real-world materials (Kazeev et al, https://arxiv.org/abs/2503.02407). Unlike generic generative models, WyFormer embeds crystallographic rules into its design, ensuring the atomic structures it generates are both original and physically plausible.

Another key component of the framework is the use of Machine Learning Interatomic Potentials (MLIPs), which help simulate atomic interactions more efficiently, particularly within complex or disordered systems. Together with DFT simulations, these tools form a closed-loop system that links generation, simulation, and validation, helping accelerate the pace of materials discovery.

With HPC support from NSCC Singapore’s ASPIRE2A supercomputer, the team trained WyFormer to generate over 100 new materials. These were then evaluated through large-scale DFT simulations, confirming that the designs were not only theoretically sound but also thermodynamically stable. Outcomes from the research was presented at International Conference on Machine Learning (ICML) 2025 in Vancouver, establishing WyFormer as a new benchmark in AI-driven materials design.

More broadly, this research demonstrates the powerful synergy between AI and automation in closing the gap between digital predictions and experimental reality—offering a scalable path forward for materials innovation.

The computational demands of Mat-GDT are immense and were only made possible through the support of NSCC Singapore. With access to national-scale HPC infrastructure, the team was able to:

- Run thousands of simulations in parallel, reducing computation runtimes from months to just days

- Train large-scale AI models efficiently using GPU acceleration and Torch JIT compilation

- Conduct high-throughput DFT testing and calculations of material designs across a broad range of material structures

Altogether, more than 1.6 million CPU core hours were consumed for DFT simulations alone. Workflow automation and task parallelisation—via tools like atomate2 and FireWorks—allowed for efficient scaling across a wide range of material structures. These optimisation techniques not only boosted throughput but also improved the reliability and consistency of the computational outputs.

Each generative model required nearly 1 million CPU core hours to complete its relaxation protocol, a scale that would be unfeasible without dedicated HPC support. Building on the success of Mat-GDT, the team is now applying similar methodologies to related projects in collaboration with A*STAR IHPC, such as the design of low thermal conductivity, high-entropy materials for thermal barrier coatings—another area where machine learning and HPC are key to accelerating innovation.

Mat-GDT introduces a faster, more targeted way to discover new materials—especially important in sectors like electronics, clean energy, and quantum computing where performance at the atomic level is critical.

The framework’s approach of combining generative AI, predictive modelling, and experimental feedback can also be applied to other fields dealing with complex design challenges, including pharmaceuticals, aerospace, and advanced manufacturing.

For the wider public, the benefits are tangible. Accelerated discovery means shorter development timelines for potentially more efficient batteries, improved energy systems, and longer-lasting devices. It also supports more sustainable innovation by reducing R&D costs and minimising resource waste.

In the next 1 to 2 years, Mat-GDT is expected to enhance materials optimisation in the electronics and manufacturing industries. Within 3 to 5 years, its applications could contribute to advances in clean energy, catalysis, and thermal management. Beyond that, it could become a foundational tool across industries that rely on high-performance materials.

Supported by a three-year Programmatic Funding Initiative under Singapore’s Research, Innovation and Enterprise 2025 (RIE2025) Manufacturing, Trade and Connectivity (MTC) domain, the team is also extending Mat-GDT into new areas including thermal coatings, catalysis, and quantum emitters—laying the groundwork for its continued evolution and broad industry impact, offering a smarter and faster way forward.

“Property-directed generative design represents a paradigm shift in materials discovery—enabling inverse design approaches that start from a desired property and generate viable structures to achieve it. This has only become possible through the convergence of advanced AI and HPC. NSCC Singapore’s computational resources were critical in scaling our work to simulate and validate complex, disordered materials with atomic-level precision. This synergy is not just accelerating discovery—it is redefining what’s possible in designing the materials of tomorrow.“

Associate Professor Kedar Hippalgaonkar

Nanyang Technological University

Principal Scientist II, A*STAR IMRE