Researchers at NTU are using HPC to automate and more accurately detect visual defects in solar panels in a bid to reduce the workload required for manual inspections.

Amid the growing interest in the renewable energy sector, the solar photovoltaic (PV) industry has witnessed an exponential growth in recent years. As new solar technologies emerge, businesses are challenged to upgrade their solar farms and recycle their existing solar installations.

Amid the growing interest in the renewable energy sector, the solar photovoltaic (PV) industry has witnessed an exponential growth in recent years. As new solar technologies emerge, businesses are challenged to upgrade their solar farms and recycle their existing solar installations.

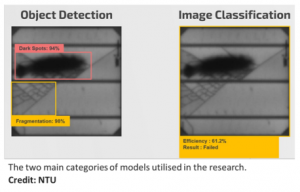

This is usually done by gauging the life expectancy and equipment effectiveness of existing solar panels by checking for visual defects. However, most inspections are currently performed manually in the industry, which requires significant manpower, time and costs. A team of researchers at Nanyang Technological University’s School of Computer Science & Engineering, in conjunction with Etavolt Pte Ltd, are tapping onto NSCC’s high performance computing resources to automate the detection of visual defects in solar panels by employing image recognition technologies and object detection models. The team seeks to significantly reduce the resources required and improve the work productivity via the developed technology in this work.

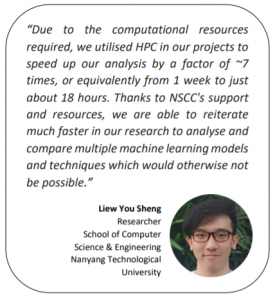

Unlike many other machine learning tools, the team is analysing multiple different models and combining their final results, which significantly amplifies the amount of computational resources required. The benefits in doing so are to identify the single best model for the solar industry and also utilise a new novel technique to combine models to improve the accuracy of detection

Unlike many other machine learning tools, the team is analysing multiple different models and combining their final results, which significantly amplifies the amount of computational resources required. The benefits in doing so are to identify the single best model for the solar industry and also utilise a new novel technique to combine models to improve the accuracy of detection

The original goal of the work was to find a model that was best suited to the collected data by the solar PV industry. The team has since expanded their work scope and are now combining multiple models through a novel ensemble technique – contextual multi-armed bandits. This allows them to better utilise the different architectures in the different machine learning models to further boost the reliability and reduce bias in the predictions, while also managing conflicting results through a deconflicting process. This method is more intuitive to the user and has resulted in an approximately 8% increase in accuracy and reliability.

“As the solar industry rapidly expands at an unprecedented rate, vast quantities of data regarding solar panel defects are generated as well. The AI-centric HPC system from NSCC has been invaluable in our research to improve on the efficiency of solar panel defect analysis,” said Mr Liew You Sheng, a researcher with the NTU team.

To find out more about the NSCC’s HPC resources and how you can tap on them, please contact [email protected].

NSCC NewsBytes August 2021

Other Case Studies

Using Digital Twin Technology to Optimise the Industrial 3D Printing Process

Researchers from the Institute of High-Performance Computing (IHPC) are utilizing supercomputers to create a digital twin that furnishes users with comprehensive information...

Accelerating electric vehicles research through HPC

Researchers from A*STAR IHPC leverage supercomputing resources to improve the performance of lithium-ion battery technology With the ever-increasing demand in energy storage...

Advancing Drug Discovery Research using NSCC HPC resources

Researchers from Nanyang Technological University (NTU) are applying variational graph encoders as an effective generalist algorithm in computer-aided drug design (CADD)....